Microbial Growth

As discussed in the blue/green levels of this chapter microbial cells use nutrients for growth, energy production and product formation as indicated in the following expression;

Nutrients + microbial cells > cell growth + energy + reaction products

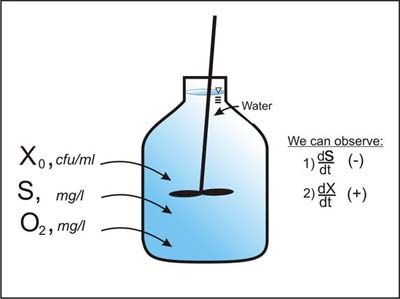

Consider the operation of the "Batch" system shown in Figure 1. This container initially contains a known growth substrate concentration S. The container is well mixed and therefore the dissolved oxygen concentration O2 does not become a limiting factor for microbial growth. Initially a known concentration X of viable microbial cells (i.e. inoculum) is added to the container and, with time, growth substrate S is utilized for cell growth. We therefore over time will observe a decrease in S (negative dS/dt) and a corresponding increase in X (positive dX/dt).

Figure 1. Microbial growth and substrate utilization in a well mixed batch container.

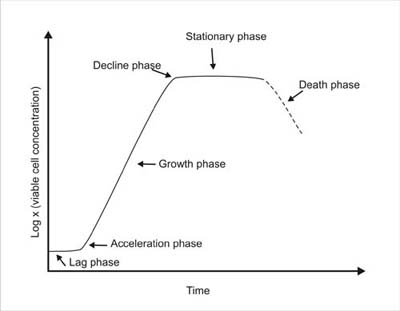

A conceptual plot of microbial cell concentration vs time for the batch system is called a growth curve, as shown in Figure 2.

Figure 2. Typical growth curve for a batch system.

Microbial Growth Kinetics

During the lag phase dX/dt and dS/dt are essentially zero. However as exponential growth phase begins it is possible to measure dX/dt and dS/dt values which are very useful for defining important microbial kinetic parameters. Using corresponding observations of dS/dt and dX/dt obtained just after the onset of exponential growth phase in Figure 2 we can compute the yield coefficient YXS and the specific growth rate µ as:Yield coefficient

![]() (1)

(1)

Specific growth rate

![]() (2)

(2)

The yield coefficient, commonly referred to as the substrate-to-biomass yield, is used to convert between cell growth rate dX/dt and substrate utilization rate dS/dt. The yield coefficient and the specific growth rate used to develop three types of microbial growth kinetic relationships; Monod , first order ,and zero order kinetics.

Monod Kinetics

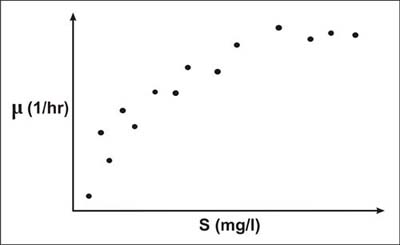

The batch experiment shown in Figure 1 can be repeated by varying initial substrate concentration S over a wide range of values—resulting in observation of individual µ values which correspond to each substrate concentration. An arithmetic plot of µ vs S will exhibit the general behavior shown in Figure 3.

Figure 3. Specific growth rate plotted respect to initial substrate concentration in a batch system.

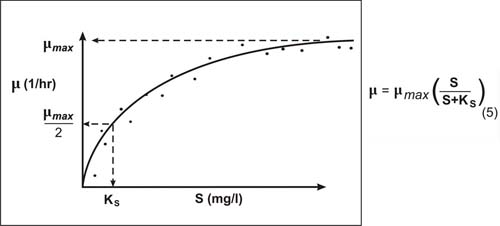

The most widely used expression for describing specific growth rate as a function of substrate concentration is attributed to Monod (1942, 1949). This expression is:

![]() (3)

(3)

Figure 4. Shows conceptually how the Monod equation is fit to the observed substrate and specific growth rate data in Figure 3. In Figure 4 it is seen that µmax is the maximum specific growth rate observed and KS is the substrate concentration corresponding to 1/2 µmax.

Figure 4. Monod Equation fit to observed data.

Monod Kinetics

By combining equations 2 and 3 we can write the following expression for time-rate-of-change of biomass:

![]() (4)

(4)

Similarly, by combining equations 1 and 3 we can write an expression for substrate utilization rate.

![]() (5)

(5)

First Order Kinetics

Equation 5 describes the Monod kinetic relationship for substrate utilization. From Figure 4 it can be seen if S << KS , Equation 5 can be approximated as:

![]() (6)

(6)

Equation 6 describes the condition where substrate utilization is proportional to substrate concentration (i.e. first order with respect to S).

Zero Order Kinetics

Likewise if S >> KS Equation 5 can be approximated as:

![]() (7)

(7)

Equation 7 describes the condition where substrate utilization rate is a constant (i.e. zero order with respect to S).